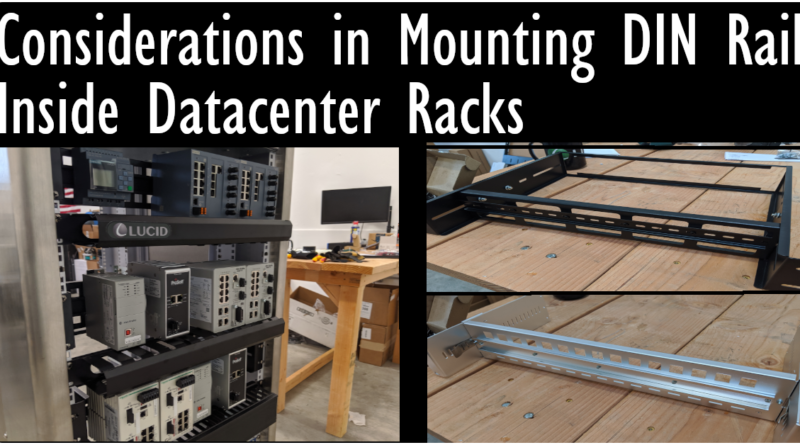

Considerations in Mounting DIN Rail Inside Datacenter Racks

Automation is moving into the datacenter. It’s cleaner, cooler, and closer to the IT infrastructure. But there are quite a few gotcha’s if you haven’t done it at scale. I’ve gotten to evaluate several DIN mounting options for 19” server racks.

Hit me up if you want details, but here is a quick list of considerations for staging:

1. Not all vendors are the same & price is not indicator of quality. The TrippLite version shown top right (beefy steel) was same cost as bottom right (stamped aluminum).

2. ELV (Extra-low voltage) Design. This gear doesn’t sit in a closed panel. It’s in the open, not always finger safe, and around possibly untrained IT staff.

3. Grounding. If your rail needs to be grounded, pay attention to the painting/powder coat on the rail mount. Consider bonding wire.

4. AC/DC power. Be mindful on how wire is routed along ethernet and other sensitive equipment.

5. Extra space. The mounts evaluated were 4U, but with devices were 5U-6U. Even larger if installing device after rail mounted in rack.

6. Fuses and Terminal blocks. Leave room for proper fusing.

If you plan on moving industrial equipment into a 4 or 2 post server rack, please contact a qualified engineer to avoid potential snags.